, prefabricated and sectional prefabricated trains, as well as export and transfer trains to the nearest freight stations of the hub and factory stations.

The formation of through trains at the marshalling station makes it possible to pass these trains without processing through many district stations and some passing marshalling stations, which speeds up the delivery of goods, the turnover of wagons and reduces the cost of transportation.

The marshalling station simultaneously processes local and transit car flows, except for those that pass through this station on departure routes from the loading point and in transit through trains.

Sorting stations are located mainly at the exits from large industrial and agricultural areas, on the approaches to large centers(cities), at large railway junctions, at points of origin of massive freight flows.

A marshalling station usually processes car flows that originate not at it, but at other stations, and the purpose of this processing is to form trains that travel the greatest possible distance along the network railways without new processing.

Marshalling stations are the main points for organizing car flows on the railway network. The fulfillment of the transportation plan, as well as the most important indicators of road performance, depend on the successful operation of the marshalling station.

Marshalling stations are located unevenly on the Russian railway network, which depends on the existing location of industrial centers and large cities along the railways in different areas, and is determined by the density of the network, the nature and size of car flows. The concentration of sorting work on powerful, technically well-equipped marshalling stations allows reducing the costs of developing marshalling stations and their equipment, making the most effective use of complex mechanization and automation, and reducing wagon downtime and operating costs.

To perform sorting work, the sorting station has humps with appropriate equipment, sorting yards, and exhaust tracks.

Marshalling stations usually have separate receiving yards for trains arriving for processing and sending yards for the formation of trains, as well as separate parks or tracks for transit trains. A group including receiving, sorting, dispatch and other parks forms a sorting system (sorting set).

Freight and passenger operations at the marshalling yard are typically small and sometimes non-existent. For boarding (disembarking) passengers on local and suburban trains, passenger stopping points are arranged on the main tracks of the station.

Local loading and unloading operations are carried out mainly on the tracks of material warehouses and individual tracks of locomotive and carriage facilities.

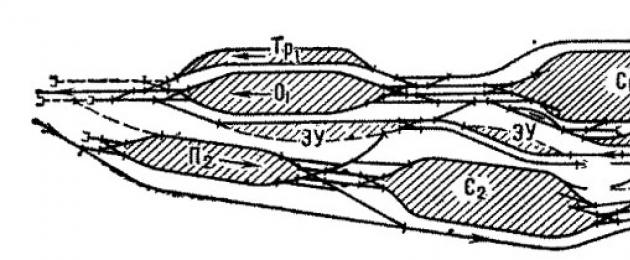

Schemes of one-way marshalling stations with a sequential arrangement of the main parks: P - receiving parks; O - departure parks; C - sorting yards; Tr - transit parks; EU - equipment devices; LH and VH - locomotive and carriage facilities; MVRP - mechanized points for current uncoupling repairs of wagons.

At the marshalling yard there are devices for locomotive and carriage facilities, water supply, energy supply, communications and signaling, as well as technical and service buildings, material warehouses and, if necessary, cargo sorting platforms, container platforms and other devices.

Sorting stations are equipped with electrical centralization of points and signals, devices for mechanized point cleaning, etc.

Depending on the value in general work On the railway network, marshalling stations are divided into main network stations (core), regional and auxiliary (to help the main or regional ones at individual nodes).

The main sorting stations are located in railway junctions where the most important main lines with powerful car flows and large local work intersect, as well as in areas of mass loading and unloading of goods when sorting car flows is necessary.

District marshalling stations process car flows that originate or are extinguished at nodes and in areas between these marshalling stations and other marshalling stations adjacent to them.

Regional marshalling yards also include port stations and industrial marshalling yards serving large industrial areas.

Humpless marshalling stations differ from hump-type sorting stations in the smaller size of wagon processing and in the smaller number of sorting tracks.

Some foreign railways have marshalling stations located on a continuous slope (towards the sorting) of the entire station or individual parks.

Depending on the relative location of the main parks, there are three types of stations: with sequential, parallel and combined arrangement of parks.

Depending on the number of sorting sets, sorting stations are of two types: one-way (one-set), in which car flows of all adjacent directions are processed in one system (schemes 1, 2), and two-way (two-set), in which one system of parks operates in an even direction of movement trains, and the other in an odd direction (Scheme 3).

In double-sided marshalling yards, humps can be in both systems or in just one. Parks in two-way marshalling yard systems can be located sequentially in one system, and combined in another.

Scheme of a two-way marshalling station: P - receiving parks; O - departure parks; C - sorting yards; Tr - transit parks; EU - equipment devices; LH and VH - locomotive and carriage facilities; MVRP - mechanized points for current uncoupling repairs of wagons.

The technology of operation of the marshalling yard is based on the method of dispatcher management of the disbanding and formation of trains and local work, ensuring best use technical means and the shortest time spent by cars at the station.

Trains arriving at the marshalling yard enter the receiving depot, where the train is prepared for disbandment and the technical and commercial condition of the cars is checked. The documents accompanying the cars are sent to the station technological center, where, based on their data, they determine which track of the sorting fleet each car from the arriving train should be directed to. A special sorting sheet is drawn up for the hump duty officer and other workers involved in the disbandment, which indicates the program for shunting work with the train.

Before disbanding, automatic mechanics release the brakes, disconnect and hang the auto-brake hoses at the points where the cuts are divided. Upon completion of preparation, the train is disbanded along the tracks of the marshalling yard in accordance with the purpose of the cars.

In the sorting yard, trains are accumulated and formed, and at the same time operations begin to prepare the train for departure. Processing of formed trains before departure includes the following operations: technical and commercial inspection and uncoupling repair of cars; connection of auto-brake hoses, selection of documents and preparation of a full-scale sheet; locomotive trailer; inspection and testing of auto brakes.

Trains passing the marshalling yard without processing or with partial processing are accepted into the transit or dispatch park on the track, where a quick change of train locomotives is ensured.

Processing of a transit train consists of the following operations: technical inspection of the train; uncoupling repair of wagons and inspection of auto brakes; commercial inspection of the composition and elimination of commercial faults; change of locomotives or locomotive crews.

Transit trains, with an increase or decrease in weight, also have a group of cars coupled or uncoupled, respectively. For transit accelerated trains transporting animals, as well as perishable goods, additional operations are carried out at the sorting station (watering livestock, equipping insulated cars, etc.).

Carrying out operations for the passage of transit trains without processing, maintenance and commercial inspection of trains and eliminating identified faults in cars, changing locomotives and locomotive crews.

The main task of a marshalling yard is to process car flows and form trains in an optimal manner, so that the time a car spends at the station is minimal and technologically justified.

Marshalling stations are the main strongholds for organizing car flows on the railway network. They are usually part of railway junctions that have passenger and freight stations. In such cases, cargo and passenger operations at the marshalling yard are carried out on a small scale. For boarding and disembarking passengers on local and suburban trains, passenger stopping points are arranged on the main tracks. Local loading and unloading operations are carried out mainly on the tracks of material warehouses and individual tracks of locomotive and carriage facilities. But some small marshalling stations may have passenger and cargo facilities approximately the same size as at a local station.

Sorting stations are located in areas of mass loading and unloading of goods, at points of convergence of highways, on approaches to large industrial centers, sea and river ports, at exit points from production basins. In most cases, the station simultaneously processes local and transit car flows, except for trains traveling long distances without being reorganized along the route.

On the railway network of the CIS countries, marshalling stations are located unevenly, due to the historical location of industrial centers and cities in different areas of the network, the nature, size and density of car flows between them.

Story

The first marshalling yard in Russia was built in 1878-1879 at the 7-8 verst of the Nikolaev Railway. In 1881, the first one-way marshalling station, Moscow-Sortirovochnaya, was built on the Moscow-Ryazan Railway. In 1899, Russia's first hump marshalling station, Rtishchevo, was built on the Ryazan-Ural Railway, and in 1901, a two-way marshalling station, Kochetovka, was built on the same road. In 1900-1910, hump marshalling stations Lyublino, Khovrino, Losinoostrovskaya, and Perovo were built. By 1917 on the railways Russian Empire there were 10 hump stations.

In 1933, the network's largest marshalling station, Sverdlovsk-Sortirovochny, was built. In 1934, the first mechanized hump was built at the Krasny Liman station, which marked the beginning of work on the reconstruction of stations with the mechanization of sorting devices. In 1946, a hump automatic centralization system (GAC) was introduced at the Bryansk station. In 1959, the first pneumatic mail was launched at the Leningrad-Sortirovochny-Moskovsky station. In 1961, the first system of automatic control of cut speed (ARS) was introduced at Losinoostrovskaya station. In the early 1960s, the total number of marshalling yards in the USSR was about 200; this number included 70 hump stations, of which 44 were mechanized.

In 2000, there were 113 marshalling stations on the Russian Ministry of Railways network. At the same time, a set of measures was taken to concentrate sorting work in the largest hubs. In order to reduce operating costs, by order of the Ministry of Railways D-787u dated April 26, 2001, 52 marshalling stations were transferred to the category of district ones, and the same instruction introduced the division of marshalling stations into core and regional.

In 2017, Perovo and Losinoostrovskaya stations were transferred to the category of district stations due to a drop in the volume of work.

Classification

By importance in the overall operation of the railway network

- network value (main or reference);

- district and auxiliary.

The main stations are located at the intersections of the most important main lines with powerful car flows and large local work, in areas of mass loading and unloading of goods when sorting car flows is necessary. The main task of these stations is the formation of long-distance routes that transit through several marshalling stations of the network. In addition, freight trains of other categories are formed at base stations. The main ones include marshalling stations, processing over 3,000 cars per day, equipped with mechanized humps.

District stations process car flows between the departure station and the nearest marshalling station. On it, local and group trains are formed, and local car flows are processed. These include marshalling stations, processing from 1,500 to 3,000 wagons per day, as well as service stations for ports and large industrial areas.

Type

- hump stations equipped with hump humps of high, medium or low power;

Depending on the number of sorting complexes

- one-sided (single-set);

- double-sided (two-set).

According to the relative position of the main parks

- with a sequential arrangement of parks;

- with a parallel arrangement of parks;

- with a combined arrangement of parks.

The layout of main tracks at marshalling yards can be extensive and one-way. However, at some stations, mostly built before the mid-20th century, the main tracks run between marshalling yards. An example of such a station is Kochetovka I.

Technologies

To carry out sorting work at stations, sorting (or hump) parks are built (the largest station park is from 20 to 40 (in Europe often 32) tracks), slides (a track on an artificially constructed hill for lowering individual cars using gravity) and exhaust ways. To carry out operations with trains, there are provision for reception parks for trains entering processing, departure parks for completed trains, as well as separate parks and tracks for the reception and departure of transit freight trains.

Reception, sorting and departure parks together with the slide and exhaust tracks form a sorting system (or set).

Sorting stations can be flat or without humps (when cars are dragged only with the help of diesel locomotives), with a slide (when cars or their couplings are “lowered down the hill” and then, through switch streets and braking posts, they themselves roll to the desired train), and stations on which the cars are accelerated by the natural slope of the tracks.

The vast majority of marshalling stations have one sorting system (cars move in one direction and in the sorting yard they process cars from both even and odd directions), two systems are possible (each system processes cars from a certain direction), or several sorting systems. The processing capacity of one-way marshalling stations reaches 6,000 wagons per day.

PURPOSE, BASIC DEVICES AND CLASSIFICATION OF SORTING STATIONS

Train transfer sheet

Sorting stations are designed for mass processing of car flows; formation of through, sectional, prefabricated, export and transfer trains. In addition, these stations process local car flows. They also carry out operations for processing transit trains without processing, repairing rolling stock, equipping locomotives, and inspection. Passenger operations at marshalling yards are carried out on a small scale (passengers boarding and disembarking from commuter and local trains at boarding platforms located near the main tracks). Freight operations for loading and unloading cargo are also carried out in a small volume on the outer tracks of the marshalling yard, on the tracks of the locomotive and carriage facilities, and on separate platforms between the station parks.

The sorting station has the following devices:

1) Reception park (receiving trains that have arrived for disbandment);

2) Sorting yard (for accumulating wagons into trains and forming trains);

3) Departure park (for preparing trains for departure and departure);

4) Transit parks (for processing transit trains without processing);

A group consisting of receiving, sorting and sending parks is called a sorting set.

5) To disband trains, there is a high- or medium-power hump, located between the reception park and the marshalling yard (at some stations, in addition to the main hump, there is a low-power hump for local trains);

6) Locomotive and carriage facilities located parallel to the reception or marshalling yard;

7) There are exhaust paths for disbanding and forming trains; connecting paths between parks; main roads and access roads of industrial enterprises.

CLASSIFICATION of marshalling stations.

I. By the number of sorting sets:

1) one-sided;

2) double-sided (there are two sorting sets, each of which processes certain directions).

II. By park location:

1) with a sequential location of the receiving park, sorting park and departure park;

2) with a combined arrangement (for example, the receiving park and the sorting park are located in series, and the departure park is parallel to the sorting station);

3) with a parallel location of all parks.

III. By location relative to main routes:

1) stations with an enclosing arrangement of main tracks;

2) with one-way main tracks;

3) with the internal location of the main tracks.

IV. By processing size:

1) low-power stations that process from 200 to 2000 cars per day;

2) medium capacity stations that process from 2000 to 5000 cars per day;

3) high-capacity stations that process more than 5,000 cars per day.

One-way marshalling yard with sequential parks.

Reception, sorting and departure parks are located sequentially and serve trains of all directions. The locomotive and carriage facilities are located on the same site parallel to the marshalling yard. This arrangement reduces the number of runs of train and shunting locomotives. It is possible to locate the locomotive and carriage facilities parallel to the reception park. In this case, it is necessary to construct additional equipment devices parallel to the sorting or departure park. Transit parks are located on both sides of the departure park and the reception park. The best option is near the departure park, because... On the tracks of the departure park and the transit park, similar operations are carried out (train processing and departure), and the tracks of these parks can be interchangeable.

A one-way sorting station with a sequential arrangement of parks has a number of ADVANTAGES: full flow of operations, increased maneuverability and processing capacity; and DISADVANTAGES: the need for additional costs for the construction of overpasses and the large length of the station site - 4-6 km.

At a one-way combined type marshalling station, one of the parks (reception or departure) is located parallel to the marshalling yard. Used when the length of the station platform is insufficient. Best location This is the case when the receiving and dispatching and sorting depots are located in series, and the departure depot is located in parallel with the sorting depot.

The locomotive facility is located on the same site as the reception depot, so the construction of an overpass is required to connect the locomotive depot and one of the departure depots.

DISADVANTAGES: complexity of shunting movements in the tail neck of the marshalling yard; many intersections of train and shunting routes; limited bandwidth.

A one-way marshalling station with an additional sorting and grouping yard, in addition to the main parks (reception, sorting and departure), has an additional sorting and grouping yard for the formation of local trains (prefabricated, export, transfer). Between the sorting yard and the sorting and grouping yard there is an additional low-power hump, which facilitates the work of the main hump in dismantling local trains. The routes of the sorting and grouping park are shorter compared to the sorting park. On a low-power hump, the shunting locomotive of the main hump or a locomotive specially allocated for this work operates.

For a low-capacity marshalling station, a two-park system is allowed (a receiving park and a marshalling park located in series with it). The accumulation of wagons into trains, their formation and preparation for departure is carried out on the same tracks of the sorting and dispatch park. The paths of the transit park are specialized in direction and are located on both sides of the reception park. The locomotive and carriage facilities can be located parallel to the sorting and dispatch depot or the receiving depot.

Operating procedure. Transit trains without processing are processed in transit depots, in accordance with their direction.

Transit trains from both directions with processing arrive at the combined reception park, then are disbanded at the hump. The cars are accumulated on the tracks of the marshalling yard, and after completion of formation they are moved to the departure yard, where they are processed for departure and sent to the line.

Processing of local cars is carried out on the tracks of locomotive and carriage facilities, on access roads, at separate sites between parks, as well as on the outer tracks of the marshalling yard.

Marshalling stations are designed for the mass disbandment and formation of freight trains, i.e. for processing car flows in significant volumes. Such stations are located at large points of origin and termination of car flows, which are divided into three categories: transit without processing, transit with processing, local.

Transit wagons without processing arrive at the station at transit trains that are not subject to disbandment. Such trains are accepted onto separate tracks of the departure park, where they undergo technical and commercial maintenance. At the same time, carriages are inspected and locomotive crews or locomotives are changed. With transit trains, if necessary, shunting work is carried out to uncouple faulty cars, change the weight and length of the train. The technology for processing transit trains at the marshalling station does not differ from the procedure for servicing such trains at the local station (see clause 5.3.).

Transit with processing and local the cars arrive at the marshalling yard as part of dismantling (recycling) trains, i.e. subject to disbandment. Transit cars with processing are accumulated and formed into new trains according to the formation plan and sent to their destination. Local cars, in addition, undergo cargo operations, after which they are also sent to their respective destinations in the trains of their formation.

To process the specified car flows, marshalling stations have a corresponding track development, which constitutes a sorting system (sorting set): arrival park; sorting hump; sorting (podgorochny) park, where the accumulation of cars and the formation of trains is carried out; departure park.

Depending on the volume of processing of car flows and local conditions, the design of station track development schemes can be one-way or two-way with a sequential, parallel arrangement of parks.

In Fig. Figure 6.1 shows a schematic diagram of the track development of a one-way marshalling station. As follows from the diagram, transit trains of both directions are accepted onto the outer tracks (T) of the departure park (O), where technical and commercial maintenance of the trains is carried out. Trains subject to disbandment arrive from all directions at the arrival depot (P), where they uncouple and clean the train locomotives, prepare the train for disbandment, and move them onto the hump.

In the process of dismantling trains from the hump in the marshalling yard (C), an accumulation of cars occurs according to the assignments of the formation plan. After completing the accumulation of cars for the size of the train, the latter is formed and rearranged to the departure depot (O), where the train is prepared for departure.

The processing capacity of one-way marshalling stations reaches 6,000 wagons per day. For greater processing capacity, double-sided sorting stations are being built (Fig. 6.2). The advantage of such stations is the flow of operations with processed cars in both even and odd directions, high processing capacity, and a reduction in the mileage of cars in direct directions.

Marshalling yards are usually adjacent to three or more approaches, which causes corner car flows traveling on lines adjacent to the station on the same side as the lines from which the cars arrived. At one-way stations, such cars, when the train is disbanded, are immediately sent to the tracks of the sub-hill park according to their specialization. At two-way stations, corner cars are first sent to a separate track in the sorting yard of a given system, then transferred to the arrival yard of another system, where they are re-sorted to destinations. Therefore, the disadvantages of two-way marshalling yards include the appearance of corner flow, which causes additional downtime, mileage and re-processing.

Depending on the construction site and local conditions, other marshalling station layouts may be used. If the construction site is not long enough, the departure depot can be located parallel to the sorting depot. In this case, the flow rate in the processing of car flows is disrupted. If the length and width of the construction site are insufficient, there may be no departure park. At the same time, the podgorochny park is a sorting and dispatching park.

Introduction. 3

1. The concept of marshalling yards. 4

2. Purpose of marshalling stations. 5

3. Construction of sorting stations. 7

4. Organization of work of sorting stations. 9

Conclusion. eleven

References.. 12

Introduction

Railways, developing, quickly formed an extensive network of railways. It was necessary to send cars not only to nearby stations, but also to more distant ones, located in different directions. To achieve this, marshalling stations began to be built at network nodes, the main purpose of which was to process car flows, i.e. disbandment and formation of trains. To carry out these works, the sorting station has special tracks and shunting means that make up a sorting set (system), which, as a rule, includes receiving, sorting, departure parks and sorting devices.

The history of the development of marshalling yards can be divided into several most characteristic stages, characterized by qualitative changes. The first stage lasted from the emergence of marshalling yards until the end of the last century, the second - until the end of the Second World War, the third continues at the present time. In each of the listed stages, especially in the last, it is also possible to distinguish periods of the most intensive development of marshalling stations.

The history of the development of sorting work at stations traces the path from completely manual operations and horse-drawn traction to high-performance complexes, where manual labor is almost completely eliminated.

Thus, the purpose of this work is to consider the essence and aspects of the operation of marshalling yards.

To achieve this goal, it is necessary to solve the following tasks:

Consider the concept of marshalling stations;

Reveal the features of the purpose of marshalling stations;

Consider the design of marshalling stations;

Describe the organization of work of marshalling yards.

1. The concept of marshalling yards

To ensure the necessary capacity and traffic safety of the railway. the lines are divided by separate points into separate parts called stretches. Separate points include: stations, sidings, passing points, waypoints, and in case of automatic blocking, traffic lights. Sidings are used for crossing and overtaking trains on single-track lines, and passing points are used for overtaking trains on double-track lines.

A station is a separate point that has track development and devices that allow certain technical, cargo, commercial and passenger operations to be carried out.

Marshalling stations differ at points of mass origin or extinction of car traffic, at points of confluence or intersection of railway lines in large transit hubs. They are intended for mass disbandment - disbandment of trains. In addition, transit trains are processed; Passenger and cargo operations are carried out on a small scale; they are usually carried out to special cargo and passenger stations, if there are any in the hub. At marshalling yards there are several signalized parks, PTOV, PTOL, depots, STC, information centers (IC), etc.

Sorting stations are stations designed for mass disbandment and formation of freight trains. They recycle here transit and local car flows from converging directions form trains traveling long distances without processing on passing stations. In addition, at marshalling yards, district police officers are formed, collection and transfer trains and also carry out operations with transit freight trains, wagon repairs, locomotive equipment, supplies water for trains with livestock, sorting of small shipments and containers.

Sorting stations are located in areas of mass loading or unloading of cargo, on the approaches to large industrial centers, in hubs railway points where there is a significant concentration of car flows. To carry out sorting work at these stations, they build sorting parks, slides, exhaust tracks. For train operations provide parks for receiving trains entering processing, parks departures of formed trains, as well as separate parks or tracks for reception and departure of transit freight trains. Reception parks, sorting and departure together with the hump form a sorting room system.

The number of tracks in marshalling yards is determined by the number of destinations and the size of car flows in accordance with the train formation plan. Number of tracks in reception, departure and transit parks determined depending on the size of the movement and the number of adjacent direction stations.

At marshalling yards there are devices for locomotive and carriage facilities, water supply, electricity supply, communications and signaling systems. Stations are equipped with modern automation and telemechanics devices.

2. Purpose of marshalling yards

Marshalling stations are intended for mass processing of cars, disbanding and formation of trains, primarily through trains (i.e. those that pass through several technical stations without processing and travel long distances) for the formation of sectional, combined, through and transfer trains.

For this purpose, the following operations are performed at marshalling yards:

1. preparing arriving trains for disbandment;

2. disbandment of trains;

3. accumulation of cars to form trains for new destinations;

4. formation of trains;

5. preparing formed trains for departure.

In addition, marshalling yards can accommodate transit trains with which the following operations are performed:

1. change of locomotive crews;

2. change of locomotives;

3. technical and commercial inspection of trains;

4. repair and equipment of locomotives, cars;

5. water supply for trains with livestock, equipment for refrigerated sections;

6. preparing cars for loading, washing cars;

7. loading and unloading wagons;

8. maintenance of access roads.

Sorting stations are located in areas of mass loading and unloading of cargo, at exits from mining areas (Kuzbass, Altaiskaya, Inskaya stations), on approaches to large industrial and administrative centers (Lyublino - Sortirovochnoe, Losinoostrovskaya), near large sea and river ports (Leningrad - sorting), at railway junctions (Moskovka, Chelyabinsk, Sverdlovsk sorting).

To perform sorting work, the sorting stations have the following technical devices: reception parks; sorting humps with appropriate equipment; sorting yards; hoods to complete the formation of compositions; departure parks.

Together, these devices form a sorting system or kit. To accommodate transit trains, there are transit tracks (sections) or transit parks. For the repair and equipping of locomotives and wagons, marshalling yards have locomotive depots with locomotive maintenance points, wagon depots with car maintenance facilities. In addition, there are telephone exchange devices, lighting, energy and water supply.

3. Construction of marshalling stations

Marshalling yards are classified depending on:

Types of sorting devices - hump and tuberculate; slide stations are equipped with slides of high, medium or low power; of the 150 hump stations, some have automated ones (Orekhovo-Zuevo, Leningrad-sorting - Moskovsky, etc.), and the majority have mechanized humps; more than 70 stations are equipped with marshalling yard automated control systems; tubercle stations have exhaust paths for disbanding trains;

Numbers of sorting kits - single-sided and double-sided; at one-way stations on the hump and in the joint venture, cars of both directions are processed and accumulated; bilateral have two systems of sorting devices, each of which processes cars of a certain (even or odd) direction; Such stations include Inskaya, Chelyabinsk - main, Lyublino, etc.

The relative location of reception, sorting and departure parks - with a parallel arrangement of all parks, sequential and combined;

Volume and nature of work - main (core) and regional; The main ones include stations that process over 3,000 cars per day, equipped with mechanized humps and forming through trains assigned to other main marshalling stations; Regional stations include stations that process from 1,500 to 3,000 cars per day and, as a rule, form through trains to the nearest marshalling stations.

Fig.1. Construction of a one-way sorting station

Fig.2. Construction of a two-way sorting station

A one-way sorting station with a sequential arrangement of parks ensures the flow of basic operations and minimal time spent on maneuvers. The disadvantage of this scheme is that the route of even-numbered dismantling trains to park P and the departure of trains of their own formation and transit from parks O and Tr2 intersect; accepting even-numbered disassemblies may cause interruptions in the operation of the slide; retrying even dismantling trains. At one-way stations, two PTOVs are usually installed - one in the reception park, the second in the area of the departure park and transit parks. Transit sections can also be located in the area of the reception park, but this does not exclude the mutual use of tracks. When placing transit parks next to Park O, it becomes possible to rearrange the formed trains along the routes of transit parks (if the tracks of Park O are busy).

A two-way sorting station with a sequential arrangement of parks provides high throughput and processing capacity, but requires high construction costs and operating costs. The disadvantage of such schemes is double processing of the corner flow.

An important element in the structure of a marshalling station is the hump. The sorting hump consists of three main elements: the sliding part - an inclined section of track that has a rise in front of the top of the hump to facilitate uncoupling of cars and stopping them in the event of termination of dismantling (50 m); the tops of the hill; descent part - a section of the path between the top of the hump and the design point located at a distance of 50-100 m from the inlet neck of the sorting yard. The difference in elevation between the top of the slide and the calculated point is called the height of the slide. This height should ensure that the car with poor driving characteristics can roll away when unfavorable conditions to calculated melancholy. Depending on the volume of wagon processing and the number of marshalling tracks, classification humps of large, medium, and low power are distinguished.

4. Organization of work of sorting stations

The organization of work at a marshalling yard depends on the volume of car flows processed, the level of technical equipment and the track development scheme.

At the PP, the processes of receiving trains, cleaning train locomotives and processing arriving trains are managed by the DSP. Control of arrows and signals is carried out using the MTC system and its remote control - manipulator. A special display is used to visually monitor the state of the PP. The chipboard has communications - loud-speaker alerts, radio communications with shunting locomotives. The processes of disbanding trains on the hump are managed by the DSPG and the hump operators. Control of the movement of trains onto the hump, their dismantling, and hump locomotives is carried out using the GAC system, radio communication with hump locomotive drivers, and loud-speaking announcement communications. DSPN controls the processes of completing the formation of trains in the joint venture, the operation of shunting locomotives on hoods, and the pulling and settling of cars on marshalling tracks. The pointers in the outlet neck of the joint venture are controlled from the shunting columns in the neck of the joint venture. DSPN coordinates its work with DSPG and DSP of the departure park. According to the instructions of the DSC, the sorting work is distributed between the hump and the hoods (prefabricated and group trains).

The processes in TrP and PO are controlled by the DSP; it prepares routes for rearranging trains in the PO, exit routes for shunting locomotives at the hood, supplying train locomotives to trains, receiving and departing transit trains, changing the locomotives of these trains. Communication - with shunting and train locomotives, loudspeaker announcements, etc.

At two-way stations, the central operational control point is located: at the hump of each system; or the control point for both systems is located between them, and the slides have only control posts for the processes of disbandment - formation.

At one-way stations - usually near the slide. If the control point is located at the hump, then the post building houses the ITC, STC, DSC, DSPG, hump operators and, as a rule, the DSP. From the inlet neck, the signalman sends documents to the STC via large-diameter pneumatic mail.

Conclusion

As a result of the work done, the concept and aspects of the operation of marshalling stations were considered.

When considering this issue, the following tasks were solved:

The concept of marshalling stations is considered;

The features of the purpose of marshalling stations are revealed;

The design of marshalling stations is considered;

The organization of work of marshalling stations is described.

So, the nature of the work of the marshalling yard depends on the category of trains and cars with which certain operations are performed. The sum of transit wagons with processing and local cars arriving and departing per day, as well as wagons in transit trains passing through the station with the change of locomotives or locomotive crews, recoupling the locomotive when changing the direction of travel, is the car turnover of the marshalling yard.

In 2003, on the railway network. there were over 12 thousand stations, of which: 10 thousand intermediate, more than 600 local stations, 230 sorting rooms, 75 passenger, more than 1200 cargo. The length of station tracks is approximately half the operational length of the railway network. During its turn, the car is at various stations about 80% of the time (including approximately 34% at technical stations, 36% at loading and unloading stations, 10% at intermediate ones).

At the stations contact is made with enterprises and settlements, numerous operations related to the transportation of passengers and the delivery of goods are carried out, car flows arise and are extinguished.

Bibliography

1. Federal Law “Charter railway transport» dated January 10, 2003 N 18-FZ. - Help system guarantor.

2. Golunov N.M. Economics of railway transport. – M.: Publishing House of the Ministry of Transport, 2003.

3. Railway on the threshold of the new millennium / Rep. Editor V.V. Kuleshov. – Novosibirsk: publishing house IEiOPP SB RAS, 2004.

4. Organization of transport work in Russia. Textbook for universities. / ed. Kuleshova A.A. – M.: Infra-M, 2003.

5. Larina N.I., Ratkovskaya T.G. Railway transport of Russia: UMK. – Novosibirsk: SibAGS, 2001.

Golunov N.M. Economics of railway transport. – M.: Publishing House of the Ministry of Transport, 2003. – p. 68.

Railway on the threshold of the new millennium / Rep. Editor V.V. Kuleshov. – Novosibirsk: publishing house IEiOPP SB RAS, 2004. – p. 101.

Organization of transport work in Russia. Textbook for universities. / ed. Kuleshova A.A. – M.: Infra-M, 2003. – p. 78.

Railway on the threshold of the new millennium / Rep. Editor V.V. Kuleshov. – Novosibirsk: publishing house IEiOPP SB RAS, 2004. – p. 107.

Larina N.I., Ratkovskaya T.G. Railway transport of Russia: UMK. – Novosibirsk: SibAGS, 2001. – p. 49.

- In contact with 0

- Google+ 0

- OK 0

- Facebook 0