GOST 12119.4-98

INTERSTATE NUMBER STANDARD

Electrical steel

METHODS FOR DETERMINING MAGNETIC AND ELECTRICAL PROPERTIES

Method for measuring specific magnetic losses and effective strength value

magnetic field

Electrical steel.

Terms used in this standard, - according to GOST 12119.0.

4 Preparation of samples for testing

5 Equipment used

The solenoid must have a frame made of non-magnetic insulating material on which the measuring winding is first placed II , then with one or more wires - the magnetizing winding I. Each wire is laid evenly in one layer.

The relative maximum difference in the amplitudes of the magnetic induction in the sample section inside the solenoid should not exceed ±5%.

6 Preparing for measurements

Where m- sample mass, kg;

D, d - outer and inner diameters of the ring, m;

γ - material density, kg/m 3 .

Material density γ, kg/m 3 , selected according to Appendix 1 of GOST 21427.2 or calculated using the formula

Where K Si and K Ai- mass fractions of silicon and aluminum, %.

where is the ratio of the density of the insulating coating to the density of the sample material,

where γ p - insulation density, taken equal to 1.610 3 kg/m 3 for inorganic coating and 1.1 · 10 3 kg/m 3 for organic;

K h - fill factor, determined as specified in GOST 21427.1.

Where l P - strip length, m.

Where l l - sheet length, m.

Where S- cross-sectional area of the sample, m 2 ;

W 2 - number of turns of winding of sample II;

r 2 - total winding resistanceII sample T2 and coils T1, Ohm;

r uh - equivalent resistance of instruments and devices connected to the winding II sample T2, Ohm, calculated by the formula

Where r V 1, r V 2, r W r A - active resistance of voltmetersPV1, PV2,wattmeter voltage circuitsPWand power amplifier voltage feedback circuits, respectively, Ohm.

The value in formula () is neglected if its value does not exceed 0.002.

Where W 1 W 2 - number of turns of sample windings T2;

μ 0 - 4 π 10 - 7 - magnetic constant, H/m;

S 0 - cross-sectional area of the sample measuring winding, m 2 ;

Sis the cross-sectional area of the sample, determined as indicated in m 2 ;

l Wed - average length of the magnetic field line, m.

For ring-shaped samples, the average length of the magnetic field linel Wed , m, is calculated using the formula

In standard tests for a sample of strips, the average lengthl Wed, m, is taken equal to 0.94 m. If it is necessary to increase the accuracy of determining magnetic quantities, values are allowedl Wed select from table.

or according to the average rectified EMF valueU avg.m , V induced in winding II coils T 1with winding I oninto the magnetizing circuit, according to the formula

Where M - mutual inductance of the coil, H; no more than 1 10-2 Gn;

f- magnetization reversal frequency, Hz.

Where m - sample weight, kg;

l P - strip length, m.

For ring samples, the effective mass is taken equal to the mass of the sample. The effective mass of a sheet sample is determined based on the results of metrological certification of the installation.

7 Measurement procedure

7.1 Determination of specific magnetic losses is based on measuring the active power spent on magnetization reversal of the sample and consumed by devicesPV 1, PV 2, PWand the amplifier feedback circuit. When testing a sheet sample, losses in yokes are taken into account. Active power is determined indirectly by the voltage on the winding II sample 72.

7.1 .1 On installation (see picture) close the keys S 2, S3, S 4and open the keyS1.

7.1.2 Set voltageU Wed, U or ( U av + Δ U), V, by voltmeterPV 1; magnetization reversal frequencyf, Hz; check with ammeter RA that wattmeterP Wnot overloaded; close the keyS 1and open the keyS2.

7.1.3 If necessary, adjust the voltmeter reading with the power sourcePV1to set the set voltage value and measure the effective voltage valueU 1, V, voltmeter PV 2and power R m, W, wattmeter P.W.

7.1.4 Set the voltage corresponding to the larger value of the magnetic induction amplitude and repeat the operations specified in , .

7.2 Determination of the effective value of the magnetic field strength is based on measuring the magnetizing current.

7.2 .1 On installation (see picture) close the keys S2, S 4and open the keysS1, S3.

7.2.2 Set voltageU cp or U, V, magnetization reversal frequencyf, Hz, and determined by ammeter RA magnetizing current valuesI, A.

7.2.3 Set a higher voltage value and repeat the operations specified in And .

Specific energy losses pa hysteresis P are the losses spent on magnetization reversal of a unit mass of material in one cycle. Specific hysteresis losses are often measured in watts per kilogram (W/kg) of magnetic material. Their value depends on the frequency of magnetization reversal and the value of the maximum induction B M. Specific hysteresis losses per cycle are determined by the area of the hysteresis loop, i.e., the larger the hysteresis loop, the greater the losses in the material.

A dynamic hysteresis loop is formed when a material is remagnetized by an alternating magnetic field and has a large area. than static, since under the action of an alternating magnetic field in the material, in addition to losses due to hysteresis, losses due to eddy currents and a magnetic aftereffect, which is determined by the magnetic viscosity of the material, appear.

Energy losses due to eddy currents P in depend on the electrical resistivity of the magnetic material. The larger the s, the lower the eddy current losses. Energy losses due to eddy currents also depend on the density of the magnetic material and its thickness. They are also proportional to the square of the amplitude of magnetic induction B M and the frequency f of the magnetic field variable.

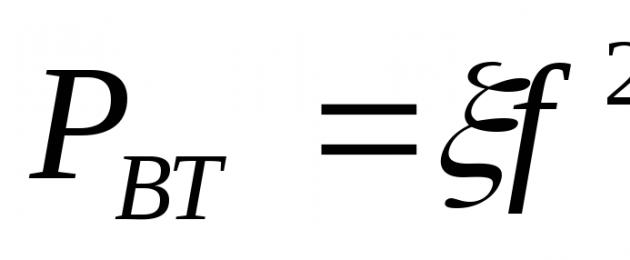

For a sheet sample of magnetic material, losses in an alternating field P in (W/kg) are calculated using the formula

where h is sheet thickness, m; In m - the maximum value (amplitude) of magnetic induction, T; f-- frequency, Hz; d -- material density, kg/m3; s -- electrical resistivity of the material, Ohm*m.

When a material is exposed to an alternating magnetic field, a dynamic magnetization curve and, accordingly, a dynamic hysteresis loop are removed. The ratio of the induction amplitude to the amplitude of the magnetic field strength on the dynamic magnetization curve represents the dynamic magnetic permeability m ~ = V m / N m.

To assess the shape of the hysteresis loop, use the squareness coefficient of the hysteresis loop K P - a characteristic calculated from the limiting hysteresis loop: K P = V n V m.

The larger the value of KP, the more rectangular the hysteresis loop. For magnetic materials used in automation and computer storage devices, KP = 0.7-0.9.

Specific volumetric energy W M (J/m3) - a characteristic used to assess the properties of magnetically hard materials - is expressed by the formula W M = (B d H d /2)M, where B d is the induction corresponding to the maximum value of the specific volumetric energy, T; H d is the magnetic field strength corresponding to the maximum value of the specific volumetric energy, A/m.

Rice. 1.6.1

Curves 1 of demagnetization and 2 of the specific magnetic energy of an open magnet are shown in Fig. 1.6.1 Curve 1 shows that at a certain value of induction B d and the corresponding magnetic field strength H d the specific volumetric energy of a permanent magnet reaches maximum value W d . This is the greatest energy created by a permanent magnet in the air gap between its poles, per unit volume of the magnet. The higher the numerical value of W M, the better the hard magnetic material and, therefore, the better the permanent magnet made from it.

The process of magnetization of magnetic materials in an alternating field is associated with the loss of part of the magnetic field power . This power, absorbed by a unit mass of magnetic material and dissipated in the form of heat, is called specific magnetic losses P, which, in turn, are the sum of losses due to hysteresis and dynamic losses. Dynamic losses are caused primarily by eddy currents and partly by magnetic aftereffects (magnetic viscosity).

Hysteresis loss associated with the phenomenon of magnetic hysteresis and irreversible movement of domain boundaries. Hysteresis losses are created during the process of displacement of domain walls at the initial stage of magnetization. Due to the heterogeneity of the structure of the magnetic material, magnetic energy is expended to move the domain walls. For each material, they are proportional to the area of the hysteresis loop and the frequency of the alternating magnetic field. The loss power P g, W/kg, consumed on hysteresis per unit mass of material, is determined by the formula

where η is a coefficient depending on the nature of the material;

B m – maximum magnetic induction during the cycle;

n – exponent having a value depending on B ranging from 1.6 to 2;

f – frequency.

To reduce hysteresis losses, magnetic materials with the lowest possible coercive force are used.

Eddy current losses are caused by electric currents that induce a magnetic flux in the material. These materials depend on the electrical resistance of the magnetic material and the shape of the core. The higher the electrical resistivity of the magnetic material, the lower the eddy current losses.

where ξ is a coefficient depending on the nature of the magnetic material, as well as its shape.

To combat eddy currents, the electrical resistance of the core (magnetic cores) is increased. With increasing frequency, eddy current losses increase more rapidly than hysteresis losses, and at a certain frequency they will begin to dominate over losses caused by hysteresis.

Losses caused by magnetic aftereffect (magnetic viscosity) are the property of magnetic materials to exhibit a dependence of the delay of the change in induction that occurs under the influence of a changing magnetic field on the duration of exposure to this field. These losses are primarily due to the inertia of the domain magnetization reversal processes. As the duration of application of the magnetic field decreases, the delays and, consequently, the magnetic losses caused by the magnetic aftereffect increase, so they must be taken into account when using magnetic materials in a pulsed operating mode.

The power loss P MF caused by the magnetic consequence is defined as the difference between the specific magnetic losses P and the sum of losses due to hysteresis P G and eddy currents P VT:

When magnetization reversal occurs in an alternating field, there is a phase lag in the magnetic induction from the magnetic field strength. This occurs as a result of the action of eddy currents, which, in accordance with Lenz’s law, prevent changes in magnetic induction, as well as due to hysteresis phenomena and magnetic aftereffects. The lag angle is called the magnetic loss angle and is designated δ M. To characterize the dynamic properties of magnetic materials, the magnetic loss tangent tgδ M is used. The figure shows a series equivalent equivalent circuit and a vector diagram of a toroidal inductor with a core made of magnetic material. Active resistance r 1 is equivalent to all types of magnetic losses, losses in the winding and electrical insulation.

If we neglect the resistance of the coil winding and its own capacitance, then from the vector diagram we obtain

where ω – angular frequency;

L – coil inductance;

Q is the quality factor of the coil with the magnetic material being tested.

The equation shows that the magnetic loss tangent is the reciprocal of the coil's quality factor.

GOST 12119.4-98

Group B39

INTERSTATE STANDARD

Electrical steel

METHODS FOR DETERMINING MAGNETIC AND ELECTRICAL PROPERTIES

Method for measuring specific magnetic losses and effective value

magnetic field strength

Electrical steel.

Methods of test for magnetic and electrical properties.

Method for measuring specific magnetic losses

and actual value of magnetic field intensity

MKS 77.040.20

OKSTU 0909

Date of introduction 1999-07-01

Preface

1 DEVELOPED by the Russian Federation, Interstate Technical Committee for Standardization MTK 120 "Metal products from ferrous metals and alloys"

INTRODUCED by Gosstandart of Russia

2 ADOPTED by the Interstate Council for Standardization, Metrology and Certification (Protocol No. 13 of May 28, 1998)

The following voted for adoption:

State name | Name of the national standardization body |

The Republic of Azerbaijan | Azgosstandart |

Republic of Armenia | Armgosstandard |

Republic of Belarus | State Standard of Belarus |

Kyrgyz Republic | Kyrgyzstandard |

Russian Federation | Gosstandart of Russia |

The Republic of Tajikistan | Tajikgosstandart |

Turkmenistan | Main State Inspectorate of Turkmenistan |

The Republic of Uzbekistan | Uzgosstandart |

Ukraine | State Standard of Ukraine |

3 Decree State Committee Russian Federation on standardization and metrology dated December 8, 1998 N 437 interstate standard GOST 12119.4-98 was put into effect directly as state standard Russian Federation since July 1, 1999

4 IN REPLACE GOST 12119-80 in part of section 4

5 REISSUE

1 area of use

1 area of use

This standard establishes a method for determining specific magnetic losses from 0.3 to 50.0 W/kg and the effective value of the magnetic field strength from 100 to 2500 A/m at magnetization reversal frequencies of 50-400 Hz using a wattmeter and ammeter.

It is possible to determine the values of magnetic quantities at magnetization reversal frequencies of up to 10 kHz on ring samples and on strip samples.

2 Normative references

This standard uses references to the following standards:

GOST 8.377-80 State system for ensuring the uniformity of measurements. The materials are soft magnetic. Methods for performing measurements when determining static magnetic characteristics

GOST 8476-93 Analogue indicating electrical measuring instruments of direct action and auxiliary parts for them. Part 3. Special requirements for wattmeters and varmeters

GOST 8711-93 Analog indicating electrical measuring devices of direct action and auxiliary parts for them. Part 2. Special requirements for ammeters and voltmeters

GOST 12119.0-98 Electrical steel. Methods for determining magnetic and electrical properties. General requirements

GOST 13109-97 Electrical energy. Electromagnetic compatibility of technical equipment. Standards for the quality of electrical energy in general-purpose power supply systems

GOST 21427.1-83 Cold-rolled anisotropic thin-sheet electrical steel. Specifications

GOST 21427.2-83 Cold-rolled isotropic thin-sheet electrical steel. Specifications

3 General requirements

General requirements to test methods - according to GOST 12119.0.

The terms used in this standard are according to GOST 12119.0.

4 Preparation of samples for testing

4.1 Test samples must be insulated.

4.2 Ring-shaped samples are collected from stamped rings with a thickness of 0.1 to 1.0 mm or wound from a tape with a thickness of no more than 0.35 mm and placed in cassettes made of insulating material with a thickness of no more than 3 mm or non-ferromagnetic metal with a thickness of no more than 0.3 mm. The metal cassette must have a gap.

The ratio of the outer diameter of the sample to the inner diameter should be no more than 1.3; The cross-sectional area of the sample is at least 0.1 cm.

4.3 Samples for the Epstein apparatus are made from strips with a thickness of 0.1 to 1.0 mm, a length of 280 to 500 mm, and a width of (30.0 ± 0.2) mm. The sample strips should not differ from each other in length by more than ±0.2%. The cross-sectional area of the sample should be from 0.5 to 1.5 cm. The number of stripes in the sample should be a multiple of four, the minimum number of stripes being twelve.

Anisotropic steel samples are cut along the rolling direction. The angle between the directions of rolling and cutting strips should not exceed 1° .

For isotropic steel samples, half of the strips are cut along the rolling direction, the other - across. The angle between the rolling and cutting directions should not exceed 5°. The strips are grouped into four packages: two - from strips cut along the rolling direction, two - across. Packages with identically cut strips are placed in parallel coils of the device.

It is allowed to cut strips at the same angle to the rolling direction. The rolling direction for all strips laid in one coil must be the same.

4.4 Sheet samples are made from 400 to 750 mm in length. The length of the sheet must be no less than the outer length of the yoke: the width of the sheet must be at least 60% of the width of the solenoid window. The tolerance for length should not exceed ±0.5%, for width - ±2 mm.

The surface and shape of the sheets must correspond GOST 21427.1 And GOST 21427.2.

5 Equipment used

5.1 Installation. The installation diagram is shown in Figure 1.

Figure 1 - Scheme for measurements using the wattmeter method

5.1.1 Voltmeters PV1 - for measuring the average rectified voltage value and subsequent determination of the amplitude of magnetic induction and РV2- to measure the effective voltage value and subsequently determine the shape coefficient of its curve, they must have a measurement limit of 30 mV to 100 V, a maximum input current of no more than 5 mA, an accuracy class of no less than 0.5 GOST 8711.

It is allowed to use a voltage divider to a voltmeter PV1 to obtain readings numerically equal to the amplitudes of magnetic induction.

5.1.2 Wattmeter PW to measure active power and subsequent determination of specific magnetic losses, it must have a measurement limit of 0.75 to 30 W, a rated power factor of no more than 0.1 at a frequency of 50 Hz and 0.2 at a higher frequency; accuracy class is not lower than 0.5 at a magnetization reversal frequency from 50 to 400 Hz or not lower than 2.5 - at a frequency of more than 400 Hz according to GOST 8476.

It is allowed to use a voltage divider to a wattmeter to obtain readings that are numerically equal to the values of specific magnetic losses. The output of the voltage divider must be connected to the parallel circuit of the wattmeter, the input - to winding II of the sample T2.

5.1.3 Ammeter RA to measure the effective value of the magnetizing current and subsequent determination of the effective value of the magnetic field strength, it must have a measurement limit of 0.1 to 5.0 A, an accuracy class of at least 0.5 according to GOST 8711. It is allowed to increase the smallest measurement limit to 1.0 A when monitoring the load of the wattmeter current circuit. The maximum power consumed by the ammeter when measuring with samples made from sheets more than 250 mm wide should be no more than 1.0 VA; for other samples - no more than 0.2 VA.

5.1.4 Frequency meter РF for measuring frequency with an error within ±0.2%.

5.1.5 The power source for magnetizing samples must have a low-frequency generator with a power amplifier or a voltage regulator with a stabilizer with a frequency of 50 Hz. The non-sinusoidal voltage coefficient of the loaded power supply should not exceed 5% GOST 13109. The rated power of the source at a magnetization reversal frequency of 50 Hz must be at least 0.45 kVA per 1.0 kg of sample mass and at least 0.3 kVA for the values indicated in Table 1.

Table 1

Magnetization reversal frequency, kHz | Sample weight, kg |

From 0.05 to 1.0 incl. | From 0.5 to 1.1 incl. |

St. 1.0 " 10.0 " | From 0.03" 0.30" |

It is possible to use an amplifier with feedback to obtain a sample magnetic flux curve shape close to sinusoidal. The non-sinusoidal coefficient of the EMF curve shape in the winding should not exceed 3%; the power consumed by the voltage feedback circuit should not exceed 5% of the measured magnetic losses.

5.1.6 Voltmeters PV1 And PV2, wattmeter voltage circuit PW and amplifier feedback should consume power no more than 25% of the measured value.

5.1.7 Coil T1 to compensate for the magnetic flux outside the sample, the number of turns of winding I should not exceed fifty, the resistance should not exceed 0.05 Ohms, and the resistance of winding II should not exceed 3 Ohms. The windings are laid on a cylindrical frame made of non-magnetic insulating material with a length of 25 to 35 mm and a diameter of 40 to 60 mm. The axis of the coil must be perpendicular to the plane of the field lines of the sample when attaching it to the Epstein apparatus. Relative difference in mutual inductance coefficients of the coil T1 and the Epstein apparatus without a sample should not exceed ±5%.

It is allowed to exclude the coil from the circuit (see Figure 1) T1 with a magnetic flux outside the sample not exceeding 0.2% of the measured value.

5.1.8 Magnetizing I and measuring II windings of the ring sample T2 must meet the requirements GOST 8.377.

5.1.9 Epstein apparatus used for testing samples composed of strips, T2 must have four coils on frames of non-magnetic insulating material with the following dimensions:

width of the internal window - (32.0±0.5) mm;

height - from 10 to 15 mm;

frame wall thickness - from 1.5 to 2.0 mm;

the length of the coil section with winding is at least 190 mm;

coil length - (220±1) mm.

The number of turns in the windings of the device is selected in accordance with Table 2.

table 2

Magnetization reversal frequency, Hz | Number of turns in the winding |

|

I - magnetizing | II - measuring |

|

From 50 to 60 incl. St. 60 "400" " 400 " 2000 " | ||

Note - The windings are wound evenly along the length of the coil frames. The number of layers of each winding on the frames must be odd. |

||

5.1.10 Sheet apparatus used for testing samples T2, must have a solenoid and two yokes. The design of the yokes must ensure parallelism of the contacting surfaces and mechanical rigidity, eliminating the influence on magnetic properties sample. The width of the poles of yokes made of electrical steel must be at least 25 mm, those of precision alloys - 20 mm. Magnetic losses in yokes should not exceed 5% of those measured; the relative difference in the amplitudes of the magnetic flux in the yokes should not exceed ±15%.

It is allowed to use devices with open yokes for measuring relative change specific magnetic losses, for example, when estimating residual voltage by GOST 21427.1.

The solenoid must have a frame made of non-magnetic insulating material, on which the measuring winding II is first placed, then the magnetizing winding I is placed with one or more wires. Each wire is evenly laid in one layer.

The relative maximum difference in the amplitudes of the magnetic induction in the sample section inside the solenoid should not exceed ±5%.

6 Preparing for measurements

6.1 Specimens made from strips, sheets or ring shapes are connected as shown in Figure 1.

6.2 Samples from strips or sheets are placed in apparatus. Samples from the strips are placed in an Epstein apparatus as indicated in Figure 2.

Figure 2 - Layout of sample strips

It is allowed to fix the position of strips and sheets in devices, creating a pressure of no more than 1 kPa perpendicular to the surface of the sample outside the magnetizing coils.

6.3 Calculate the cross-sectional area, m, of the samples:

6.3.1 Cross-sectional area, m, for ring-shaped samples made of material with a thickness of at least 0.2 mm is calculated using the formula

Where -

sample weight, kg;

- outer and inner diameters of the ring, m;

- material density, kg/m.

Material density, kg/m, selected according to Appendix 1 GOST 21427.2 or calculated using the formula

where and -

mass fractions of silicon and aluminum, %.

6.3.2 Cross-sectional area, m, for ring-shaped samples made of material less than 0.2 mm thick is calculated using the formula

where is the ratio of the density of the insulating coating to the density of the sample material,

where is the insulation density, taken equal to 1.6 10 kg/m for an inorganic coating and 1.1 10 kg/m for an organic one;

- fill factor, determined as specified in GOST 21427.1

6.3.3 Cross-sectional area S, m, samples composed of strips for the Epstein apparatus are calculated using the formula

where is the length of the strip, m.

6.3.4 Cross-sectional area of the sheet sample, m, is calculated using the formula

where is the length of the sheet, m.

6.4 The error in determining the mass of samples should not exceed ±0.2%, the outer and inner diameters of the ring - ±0.5%, the length of the strips - ±0.2%.

6.5 Measurements at a magnetic induction amplitude value of less than 1.0 Tesla are carried out after demagnetization of the samples in a field with a frequency of 50 Hz.

Set the voltage corresponding to the magnetic induction amplitude of at least 1.6 Tesla for anisotropic steel and 1.3 Tesla for isotropic steel, then gradually reduce it.

The demagnetization time must be at least 40 s.

When measuring magnetic induction in a field of less than 1.0 A/m, the samples are kept after demagnetization for 24 hours; when measuring induction in a field with a strength of more than 1.0 A/m, the exposure time can be reduced to 10 minutes.

It is allowed to reduce the exposure time if the relative difference in induction values obtained after normal and shortened exposures is within ±2% .

6.6 The upper limits of the values of the measured magnetic quantities for ring-shaped samples and those composed of strips must correspond to a magnetic field strength amplitude of no more than 5 10 A/m at a magnetization reversal frequency of 50 to 60 Hz and no more than 1 10 A/m at higher frequencies; lower limits - the lowest values of magnetic induction amplitudes given in Table 3.

Table 3

Magnetization reversal frequency, kHz | The smallest value of the magnetic induction amplitude, T, during measurement |

|

specific magnetic losses, W/kg | magnetic field strength, A/m |

|

From 0.05 to 0.06 incl. | ||

St. 0.06 " 1.0 " | ||

" 1,00 " 10,0 " | ||

The smallest value of the magnetic induction amplitude for sheet samples should be equal to 1.0 Tesla.

6.7 For voltmeter PV1, calibrated in average rectified values, the voltage, V, corresponding to a given magnetic induction amplitude, T, and magnetization reversal frequency, Hz, is calculated by the formula

Where -

cross-sectional area of the sample, m;

- number of turns of winding of sample II;

- total resistance of the winding of sample II T2 and coils T1, Ohm;

- equivalent resistance of instruments and devices connected to the winding of sample II T2, Ohm, calculated by the formula

Where -

active resistance of voltmeters PV1, PV2, wattmeter voltage circuits PW and power amplifier voltage feedback circuits, respectively, Ohm.

The value in formula (6) is neglected if its value does not exceed 0.002.

6.8 For voltmeter PV1, calibrated in effective values of sinusoidal voltage, the value of U, V, calculated by the formula

6.9 If there is no coil T1 calculate the correction , B, due to the magnetic flux outside the sample, using the formula

where is the number of turns of the sample windings T2;

- magnetic constant, H/m;

- cross-sectional area of the sample measuring winding, m;

- cross-sectional area of the sample, determined as specified in 6.3, m;

- average length of the magnetic field line, m.

For ring-shaped samples, the average length of the magnetic field line, m, is calculated using the formula

In standard tests for a sample of strips, the average length, m, is taken equal to 0.94 m. If it is necessary to increase the accuracy of determining magnetic quantities, values can be selected from Table 4.

Table 4

Magnetic field strength, A/m | Average length of magnetic field line, m |

|

for isotropic steel | for anisotropic steel |

|

From 0 to 10 incl. St. 10 "70" | ||

For a sheet sample, the average length of the magnetic field line, m, is determined based on the results of metrological certification of the installation;

- current amplitude, A; calculated depending on the amplitude of the voltage drop, V, across a resistor with resistance, Ohm, included in the magnetizing circuit, according to the formula

or by the average rectified value of the emf, V, induced in winding II of the coil T1 when winding I is connected to the magnetizing circuit, according to the formula

Where -

mutual inductance of the coil, H; no more than 1·10 Hn;

- magnetization reversal frequency, Hz.

6.10 When determining specific magnetic losses in the Epstein apparatus, one should take into account the inhomogeneity of magnetization of the corner parts of the magnetic circuit by introducing the effective mass of the sample, kg, which for samples from strips is calculated by the formula

Where -

sample weight, kg;

- strip length, m.

For ring samples, the effective mass is taken equal to the mass of the sample.

The effective mass of a sheet sample is determined based on the results of metrological certification of the installation.

7 Measurement procedure

7.1 Determination of specific magnetic losses is based on measuring the active power spent on magnetization reversal of the sample and consumed by devices PV1, PV2, PW and the amplifier feedback circuit. When testing a sheet sample, losses in yokes are taken into account. Active power is determined indirectly by the voltage on winding II of sample T2.

7.1.1 At the installation (see Figure 1) the keys are closed S2, S3, S4 and open the key S1.

7.1.2 Set the voltage, or (), V, using a voltmeter PV1; magnetization reversal frequency, Hz; check with ammeter RA, what is a wattmeter PW not overloaded; close the key S1 and open the key S2.

7.1.3 If necessary, adjust the voltmeter reading with the power source PV1 to set the set voltage value and measure the effective voltage value, V, with a voltmeter PV2 and power, W, wattmeter P.W.

7.1.4 Set the voltage corresponding to the larger value of the magnetic induction amplitude and repeat the operations specified in 7.1.2, 7.1.3.

7.2 Determination of the effective value of the magnetic field strength is based on the measurement of the magnetizing current.

7.2.1 At the installation (see Figure 1) the keys are closed S2, S4 and open the keys S1, S3.

7.2.2 Set the voltage or U, V, magnetization reversal frequency, Hz, and is determined using an ammeter RA values of magnetizing current, A.

7.2.3 Set a higher voltage value and repeat the operations specified in 7.2.1 and 7.2.2.

8 Rules for processing measurement results

8.1 The voltage curve shape factor on winding II of sample is calculated using the formula

Where -

effective voltage value, V;

-

voltage calculated using formula (6), V.

8.2 Specific magnetic losses, W/kg, of a strip or ring-shaped sample are calculated using the formula

where is the effective mass of the sample, kg;

- average power value, W;

- effective voltage value, V;

- number of turns of sample windings T2;

- see 6.7.

The values and are neglected if the ratio does not exceed 0.2% of and the ratio does not exceed 0.002.

The error in determining the resistance should not exceed ±1%.

It is allowed to substitute a value equal to 1.11 instead of voltage at =

1,

- In contact with 0

- Google+ 0

- OK 0

- Facebook 0