Measurement- this is finding the value of a physical quantity empirically using special technical means. Measurements are classified according to: ♦ way of obtaining information; ♦ the nature of changes in the quantity in the process of its measurement; ♦ the amount of measurement information; ♦ relation to the main units of measurement. According to the method of obtaining information, measurements are divided into direct indirect, cumulative and joint. By the nature of changes in the measured value during the measurement process allocate statistical, dynamic and static measurements.

By amount of measurement information distinguish between single and multiple measurements. relation to the main units of measurement distinguish between absolute and relative measurements.

Measurement principle - the physical phenomenon or effect underlying the measurements (for example, the use of the Doppler effect to measure speed - takes place in any wave process of energy propagation; the use of gravity when changing mass by weighing).

Measurement method - this is a technique or a set of techniques for comparing the measured physical quantity with its unit in accordance with the implemented measurement principle (the measurement method is usually determined by the device of measuring instruments)

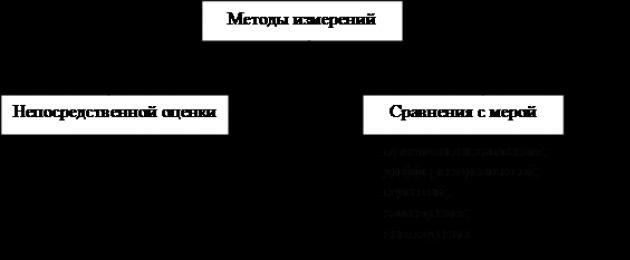

There are the following measurement methods: methods of direct evaluation of measurements (the value of the quantity is determined directly by the indicating measuring instrument); .♦ methods of comparison with a measure (the measured quantities are compared with the quantities that reproduce the measure); ♦ null measurement method (the resulting effect of the measured quantity and measure on the comparator is brought to zero); ♦ substitution measurement method (the measured quantity is replaced by a measure with a known value of the quantity); so that the comparator is affected by their sum equal to a predetermined value); ♦ differential measurement method (the measured value is compared with a homogeneous value that has a known value that differs slightly from the value of the measured value when the difference between these two values is measured); ♦ contact method of measurement (measurement of the shaft diameter with a measuring clamp or a through and through gauge); Measurement technique is an established set of operations and rules for measurement.

Physical quantities as objects of measurement A physical quantity is one of the properties of a physical object, which is qualitatively common for many physical objects, but quantitatively individual for each of them. Measured physical quantity represents a quantitative physical quantity to be measured, measured or measured in accordance with the main purpose of the measurement task. System of units of physical quantities- this is a set of basic and derived physical quantities, formed in accordance with accepted principles, when some quantities are taken as independent, while others are their functions. Basic is a physical quantity included in a system of quantities and conditionally accepted as independent of other quantities of this system. derivative called the physical quantity included in the system and determined through the basic quantities of this system.

The basic quantities are independent of each other, but they can serve as the basis for establishing relationships with other physical quantities, which are called derivatives of them. For example, Einstein's formula includes the basic unit - mass and the derived unit - energy. The main quantities correspond to the basic units of measurement, and the derivatives correspond to the derivatives. Each physical quantity has a certain dimension - an expression in the form of a power monomial, composed of products of symbols of basic physical quantities in various degrees, reflecting the relationship of a given physical quantity with physical quantities accepted in this system of quantities as basic, and with a proportionality coefficient equal to one.

22. Means of measuring temperature. There are two main ways to measure temperatures - contact and non-contact. Contact methods are based on the direct contact of the temperature measuring transducer with the object under study, as a result of which the state of thermal equilibrium of the transducer and the object is achieved. This method has its drawbacks. The temperature field of the object is distorted when a thermal receiver is introduced into it. The temperature of the transducer is always different from the true temperature of the object. The upper limit of temperature measurement is limited by the properties of the materials from which the temperature sensors are made. In addition, a number of problems of temperature measurement in inaccessible objects rotating at high speed cannot be solved by the contact method.

The non-contact method is based on the perception of thermal energy transmitted through radiation and perceived at a certain distance from the volume under study. This method is less sensitive than contact. Temperature measurements to a large extent depend on the reproduction of calibration conditions during operation, otherwise significant errors appear. A device used to measure temperature by converting its values into a signal or indication is called a thermometer (GOST 13417-76),

According to the principle of operation, all thermometers are divided into the following groups, which are used for different temperature ranges: 1 Expansion thermometers from -260 to +700 ° C, based on the change in volumes of liquids or solids with temperature changes. 2 Manometric thermometers from -200 to +600 °C, measuring temperature by the dependence of the pressure of a liquid, vapor or gas in a closed volume on temperature changes.3. Electrical resistance thermometers are standard from -270 to +750 °C, converting temperature change into a change in the electrical resistance of conductors or semiconductors. 4. Thermoelectric thermometers (or pyrometers), standard from -50 to +1800 °C, the conversion of which is based on the dependence of the value of the electromotive force on the temperature of the junction of dissimilar conductors.

Radiation pyrometers from 500 to 100,000 °C, based on measuring temperature by the value of the intensity of radiant energy emitted by a heated body, Thermometers based on electrophysical phenomena from -272 to +1000 °C (thermonoise thermoelectric converters, volumetric resonant thermal converters, nuclear resonant ones).

Metrology, standardization and certification

General questions of the basics of metrology and measuring technology

In practical life, man everywhere deals with measurements. At each step, there are measurements of such quantities as length, volume, weight, time, etc.

Measurements are one of the most important ways of understanding nature by man. They give quantitative characteristic of the surrounding world, revealing to man the laws operating in nature. All branches of technology could not exist without an extensive system of measurements that determine both all technological processes, their control and management, and the properties and quality of manufactured products.

The branch of science that studies measurements is metrology. The word "metrology" is formed from two Greek words: metron - measure and logos - doctrine. The literal translation of the word "metrology" is the doctrine of measures. For a long time, metrology remained mainly a descriptive science of various measures and the relationships between them. Since the end of the 19th century, thanks to the progress of the physical sciences, metrology has developed significantly. A major role in the development of modern metrology as one of the sciences of the physical cycle was played by D. I. Mendeleev, who led domestic metrology in the period 1892-1907.

In accordance with GOST 16263-70 “Metrology. Terms and Definitions": metrology is the science of measurements, methods and means of ensuring their unity and ways to achieve the required accuracy.

Unity of measurements- such a state of measurements in which their results are expressed in legal units and measurement errors are known with a given probability. The unity of measurements is necessary in order to be able to compare the results of measurements taken in different places, in different time, using different methods and measuring instruments.

Accuracy of measurements characterized by the proximity of their results to the true value of the measured quantity. Accuracy is the reciprocal of errors(it will be discussed below).

Measuring technology is a practical, applied area of metrology.

The measured quantities that metrology deals with are physical quantities, i.e., the quantities included in the equations of the experimental sciences (physics, chemistry, etc.) involved in the knowledge of the world empirical(T.

e. experimentally) by.Metrology penetrates into all sciences and disciplines dealing with measurements, and is a single science for them.

The main concepts that metrology operates on are as follows:

Physical quantity;

Unit of physical quantity;

System of units of physical quantities;

The size of a unit of a physical quantity (transferring the size of a unit of a physical quantity);

Means of measurement of a physical quantity;

exemplary measuring instrument;

Working measuring instrument;

Measurement of a physical quantity;

Measurement method;

Measurement result;

Measurement error;

Metrological service;

Metrological support, etc.

Let's define some basic concepts:

Physical quantity- a characteristic of one of the properties of a physical object (phenomenon or process), which is qualitatively common for many physical objects, but quantitatively individual for each object (i.e., the value of a physical quantity can be for one object a certain number of times more or less than for the other). For example ": length, time, electric current strength.

Unit of physical quantity- a physical quantity of a fixed size, which is conventionally assigned a numerical value equal to 1, and used to quantify homogeneous physical quantities. For example: 1 m is a unit of length, 1 s is time, 1A is the strength of the electric current.

System of units of physical quantities- a set of basic and derived units of physical quantities, formed in accordance with accepted principles for a given system of physical quantities. For example: International system units (SI), adopted in 1960

In the system of units of physical quantities, there are basic units of the system of units(in SI - meter, kilogram, second, ampere, kelvin). From the combination of basic units are formed derived units(velocities - m / s, density - kg / m 3).

By adding prefixes to the basic units, multiples (for example, a kilometer) or submultiples (for example, a micrometer) units are formed.

Historically, the first system of units of physical quantities was the metric system adopted in 1791 by the National Assembly of France. It was not yet a system of units in the modern sense, but included units of lengths, areas, volumes, capacities and weights, which were based on two units: the meter and the kilogram.

In 1832, the German mathematician K. Gauss proposed a method for constructing a system of units as a set of basic and derivatives. He built a system of units, in which three arbitrary units independent of each other were taken as the basis - length, mass and time. All other units could be defined using these three. Such a system of units, connected in a certain way with the three main ones, Gauss called the absolute system. For the basic units, he took the millimeter, milligram and second.

Later, with the development of science and technology, a number of systems of units of physical quantities appeared, built according to the principle proposed by Gauss, based on the metric system of measures, but differing from each other in basic units.

Consider the main systems of units of physical quantities.

SGS system. The CGS system of units of physical quantities, in which the basic units are the centimeter as a unit of length, the gram as a unit of mass and the second as a unit of time, was established in 1881.

MKSS system. The use of the kilogram as a unit of weight, and subsequently as a unit of force in general, led at the end of the 19th century to the formation of a system of units of physical quantities with three basic units: a meter - a unit of length, a kilogram-force - a unit of force and a second - a unit of time.

ISS system. The foundations of this system were proposed in 1901 by the Italian scientist Giorgi. The basic units of the MKSA system are the meter, kilogram, second, and ampere.

The presence of a number of systems of units of physical quantities, as well as a significant number of non-systemic units, the inconvenience associated with recalculation during the transition from one system of units to another, required the unification of units of measurement. Growth of scientific and technical and economic ties between different countries necessitated such unification on an international scale.

A unified system of units of physical quantities was required, practically convenient and covering various areas of measurement. At the same time, it had to preserve the principle of coherence (equality to unity of the coefficient of proportionality in the equations of connection between physical quantities).

In 1954, the X General Conference on Weights and Measures established six basic units (meter, kilogram, second, ampere, kelvin, candela + mole). The system, based on the six basic units approved in 1954, was called the International System of Units, abbreviated as SI (SI is the initial letters of the French name Systeme International). A list of six basic, two additional and the first list of twenty-seven derived units was approved, as well as prefixes for the formation of multiples and submultiples.

In the Russian Federation, the SI system is regulated by GOST 8.417-81.

The size of the unit of physical quantity- quantitative certainty of the unit of physical quantity, reproduced or stored by the measuring instrument. The size of the base SI units is established by the definition of these units by the General Conferences on Weights and Measures (CGPM). Thus, in accordance with decision XIII of the CGPM, the unit of thermodynamic temperature, the kelvin, was set equal to 1/273.16 of the thermodynamic temperature of the triple point of water.

Reproduction of units is carried out by national metrological laboratories using national standards. The difference between the size of the unit reproduced by the national standard and the size of the unit as determined by the CGPM is established during international comparisons of standards.

Unit size stored exemplary (OSI) or workers (RSI) means of measurement, can be set in relation to the national primary standard. In this case, there may be several stages of comparison (through secondary standards and OSI).

Measurement of a physical quantity- a set of operations for the use of a technical means that stores a unit of a physical quantity, which consists in comparing (explicitly or implicitly) the measured quantity with its unit in order to obtain this quantity in the most convenient form for use.

Measuring principle- a physical phenomenon or effect underlying measurements by one or another type of measuring instruments.

Application of the Doppler effect to measure speed;

Application of the Hall effect to measure induction magnetic field;

Using gravity to measure mass by weighing.

Measurement types

By the nature of the dependence of the measured value on time measurements are divided into:

static, at which the measured value remains constant in time;

dynamic, during which the measured value changes and is not constant in time.

Static measurements are, for example, measurements of body dimensions, constant pressure, electrical quantities in circuits with a steady state, dynamic measurements are measurements of pulsating pressures, vibrations, electrical quantities under transient conditions.

According to the method of obtaining measurement results they are divided into:

indirect;

cumulative;

joint.

Direct- These are measurements in which the desired value of a physical quantity is found directly from experimental data.

Direct measurements can be expressed by the formula , where is the desired value of the measured quantity, and is the value directly obtained from the experimental data.In direct measurements, the measured quantity is subjected to experimental operations, which is compared with the measure directly or with the help of measuring instruments graduated in the required units. Examples of straight lines are measurements of body length with a ruler, mass with the help of scales, etc.

Indirect- these are measurements in which the desired value is determined on the basis of a known relationship between this value and the quantities subjected to direct measurements, i.e. they measure not the quantity itself determined, but others that are functionally related to it. The value of the measured quantity is found by calculating according to the formula

Examples of indirect measurements: determining the volume of a body by direct measurements of its geometric dimensions, finding the electrical resistivity of a conductor by its resistance, length and cross-sectional area.

Indirect measurements are common in cases where the desired value is impossible or too difficult to measure directly, or when direct measurement gives a less accurate result. Their role is especially great when measuring quantities that are inaccessible to direct experimental comparison, for example, the dimensions of the astronomical or intraatomic order.

Cumulative- these are simultaneous measurements of several quantities of the same name, in which the desired value is determined by solving a system of equations obtained by direct measurements of various combinations of these quantities.

An example of cumulative measurements is the determination of the mass of individual weights of a set (calibration by the known mass of one of them and by the results of direct comparisons of the masses of various combinations of weights).

Joint- these are simultaneous measurements of two or more dissimilar quantities to find dependencies between them.

An example is the measurement of electrical resistance at 20 0 C and the temperature coefficients of the measuring resistor according to direct measurements of its resistance at various temperatures.

Measurement methods

Method of measurement- this is a method of experimentally determining the value of a physical quantity, i.e. the totality used in the measurements physical phenomena and measuring instruments.

Direct evaluation method consists in determining the value of a physical quantity using the reading device of a direct-acting measuring device. For example, measuring voltage with a voltmeter.

This method is the most common, but its accuracy depends on the accuracy of the measuring instrument.

Method of comparison with a measure - in this case, the measured value is compared with the value reproduced by the measure. The accuracy of the measurement may be higher than the accuracy of the direct estimate.

There are the following varieties of the comparison method with a measure:

Contrasting method, in which the measured and reproducible value simultaneously act on the comparison device, with the help of which the ratio between the quantities is established. Example: measuring weight with a balance scale and a set of weights.

Differential Method, at which the measuring instrument is affected by the difference between the measured value and the known value reproduced by the measure. In this case, the balancing of the measured value of the known is not completely performed. Example: voltage measurement direct current using a discrete voltage divider, a reference voltage source and a voltmeter.

Zero Method, at which the resulting effect of the impact of both quantities on the comparison device is brought to zero, which is recorded by a highly sensitive device - a null indicator. Example: measuring the resistance of a resistor using a four-arm bridge in which the voltage drop across a resistor of unknown resistance is balanced by the voltage drop across a resistor of known resistance.

substitution method, in which the measured value and the known value are alternately connected to the input of the device, and the value of the measured value is estimated from two readings of the device, and then by selecting the known value, both readings are matched. With this method, high measurement accuracy can be achieved with a high accuracy of a measure of a known value and a high sensitivity of the device. Example: accurate accurate measurement of small voltage using a highly sensitive galvanometer, to which an unknown voltage source is first connected and the deviation of the pointer is determined, and then the same pointer deviation is achieved using an adjustable source of known voltage. In this case, the known voltage is equal to the unknown.

Match Method, at which the difference between the measured value and the value reproduced by the measure is measured, using the coincidence of scale marks or periodic signals. Example: measuring the speed of a part using a flashing strobe lamp: observing the position of the mark on the rotating part at the moments of the flashes of the lamp, the known speed of the flashes and the offset of the mark determine the speed of the part.

The measurement of physical quantities consists in comparing any quantity with a homogeneous quantity, taken as a unit. In metrology, the term "measurement" is used, which means finding the value of a physical quantity empirically using special technical means.

Measurements performed with the help of special technical means are called instrumental. The simplest example of such measurements is determining the size of a part with a ruler with divisions, that is, comparing the size of a part with a unit of length stored by a ruler.

Derived from the term "measurement" is the term "measure", widely used in practice. There are terms "measure", "measure", "measure", but their use in metrology is unacceptable.

To streamline the measurement activity, measurements are classified according to the following criteria:

General methods of obtaining results - direct, indirect, compatible, cumulative;

The number of measurements in a series - single and multiple;

Metrological purpose - technical, metrological;

Characteristics of accuracy - equal and unequal;

Relation to the change in the measured value - statistical and dynamic;

Expression of the measurement result - absolute and relative;

Direct measurements - measurements in which the desired value of a quantity is found directly from experimental data (measurements of mass on scales, temperature of thermometers, length using linear measures). In direct measurements, the object of study is brought into interaction with measuring instruments and, according to the testimony of the latter, the value of the measured quantity is counted. Sometimes the instrument readings are multiplied by a coefficient, appropriate corrections are introduced, etc. These measurements can be written as an equation: X \u003d C X P,

where X is the value of the measured quantity in units accepted for it;

C is the price of a scale division or a single reading of a digital reading device in units of the measured value;

X P - reading on the indicator device in scale divisions.

Indirect measurements - measurements, at which the desired value is found on the basis of the known relationship between this value and the values \u200b\u200bobtained by direct measurements (determination of the density of a homogeneous body by its mass and geometric dimensions, the electrical resistivity of the conductor by its resistance, length and cross-sectional area). In the general case, this dependence can be represented as a function X = (X1,X2,....,Xn), in which the value of the arguments X1, X2, ....,Xn is found as a result of direct, and sometimes indirect, joint or cumulative measurements .

For example, the density of a homogeneous solid bodyρ is found as the ratio of the mass m to its volume V, and the mass and volume of the body are measured directly: ρ=m/V.

To improve the accuracy of measurements of density ρ, mass m and volume V are measured repeatedly. In this case, the density of the body

ρ = m/V , m is the result of body weight measurement, m = 1/n Σ m i ;

V=ΣVi/n - the result of measuring the volume of the body Π.

Cumulative measurements - measurements of several homogeneous quantities, in which the desired value of the quantities is found by solving a system of equations obtained by direct measurements of various combinations of these quantities (measurements in which the mass of individual weights of the set are found from the known mass of one of them and from the results of direct comparisons of the masses of various combinations of weights ).

Joint measurements - simultaneous measurements of two or more opposite quantities to find the relationship between them (simultaneously measuring the increment in the length of the sample depending on changes in its temperature and determining the coefficient of linear expansion).

Joint and cumulative measurements are very close in terms of the methods of finding the desired values of the measured quantities. The difference lies in the fact that with cumulative measurements, several quantities of the same name are simultaneously measured, and with joint measurements, opposite ones. The values of the measured quantities x1, ..., xn are determined on the basis of the cumulative equations;

F1 (X1, ..., Xm, X11, ... , X1n);

F2 (X1, ..., Xm, X21, ... , X1n);

Fn (X1, ..., Xm, Xk1, ... , Xkn),

where X11, X21, ……………..Xk n - values measured by direct methods.

Joint measurements are based on well-known equations that reflect the relationships existing in nature between the properties of objects, i.e. between quantities.

Absolute measurements are measurements based on direct measurements of one or more basic quantities and the use of physical constants.

Relative measurements - obtaining the ratio of a value to the value of the same name, which plays the role of a unit, or a change in the value in relation to the value of the same name, taken as the initial one.

Single measurement- measurement, performed once (measurement of a specific time by the clock).

Multiple measurements - measurements of the same physical quantity, the result of which is obtained from several consecutive measurements. Typically, multiple measurements are those that are made more than three times.

Technical measurements - measurements performed using working measuring instruments in order to control and manage scientific experiments, control product parameters, etc. (measurement of air pressure in the automobile chamber).

Metrological measurements - measurements using standards and exemplary measuring instruments with the aim of innovating units of physical quantities or transferring their sizes to working measuring instruments.

Equivalent measurements - row measurements of any value, made by measuring instruments of the same accuracy in the same conditions.

Unequal measurements - a series of measurements of any value, made with different accuracy with measuring instruments and under different conditions.

Static measurements - measurements of a physical quantity, taken in accordance with a specific measurement task, as unchanged over the measurement time (measuring the size of a part at normal temperature).

Dynamic measurements - measurements of a physical quantity, the size of which changes over time (measurements of the distance to ground level from a descending aircraft).

Measuring instruments

Measuring instruments are technical means used in measurements and having normalized metrological properties. Depends on the means of measurement correct definition the value of the measured quantity in the process of its measurement. Measuring instruments include: measures: measuring instruments, measuring installations, measuring systems.

Measure - a measuring instrument designed to reproduce a physical quantity of a given size (a weight is a measure of mass, a generator is a measure of the frequency of electrical oscillations). Measures, in turn, are divided into single-valued and multi-valued.

Unambiguous measure - measure, reproducing a physical quantity of the same size (plane-parallel end measure of length, normal element, capacitor of constant capacitance),

multi-valued measure - a measure that reproduces a series of physical quantities of the same name of various sizes (ruler: in millimeter divisions, a capacitor of variable capacitance).

A set of measures is a specially selected set of measures used not only individually, but also in various combinations in order to reproduce a number of similarly named quantities of various sizes (a set of weights, a set of plane-parallel end measures of length).

A measuring device is a measuring device designed to generate a signal of measuring information in a form accessible to direct perception by an observer. The results of measurements are issued by the reading devices of the instruments, which can be scale, digital and recording.

Scale reading devices consist of a scale, which is a set of marks and numbers depicting a series of successive values of the measured value, and a pointer (pointer, electron beam, and others) associated with the moving system of the device.

Scale marks with numerical values represented are called numerical scale marks. The main characteristics of the scale are the length of the scale division, which is expressed by the distance between the axes of two adjacent scale strokes, and the scale division value, which represents the value of the measured quantity that causes the pointer to move one division.

It is also customary to single out the concepts: range of measurements and range of indications.

The measurement range is part of the range of indications for which the limits of permissible errors of measuring instruments are normalized. The smallest and largest values of the measurement range are called the lower and upper limits of the measurements, respectively.

The value of a quantity determined by the reading device of the measuring instrument and expressed in the accepted units of this quantity is called the indication of the measuring instrument.

The measured value is determined either by multiplying the number of scale divisions by the scale division value or by multiplying the numerical value read on the scale by the scale constant.

Currently, either mechanical or light digital readout devices are widely used.

Recording reading devices consist of a writing or printing mechanism and a tape. The simplest writing device is a pen filled with ink, which fixes the measurement result on a paper tape. In more complex devices, the recording of the measurement result can be carried out by a light or electron beam, the movement of which depends on the values of the measured quantities.

A measuring instrument (MI) is a technical instrument intended for measurements, having normalized metrological characteristics, reproducing or storing a unit of physical quantity, the size of which is taken unchanged over a known time interval.

The above definition expresses the essence of the measuring instrument, which, firstly, stores or reproduces the unit, and secondly, this unit is unchanged. These critical factors and determine the possibility of carrying out measurements, i.e. make a technical tool a means of measurement. This means of measurement differs from other technical devices. Measuring instruments include measures, measuring: transducers, instruments, installations and systems.

A measure of a physical quantity is a measuring instrument designed to reproduce and (or) store a physical quantity of one or more given dimensions, the values of which are expressed in established units and are known with the required accuracy. Examples of measures: weights, measuring resistors, end measures of length, radionuclide sources, etc. Measures that reproduce physical quantities of only one size are called unambiguous (weight), several sizes are multi-valued (millimetric ruler - allows you to express the length both in mm and in cm). In addition, there are sets and magazines of measures, for example, a magazine of capacitances or inductances. When measuring using measures, the measured values are compared with known values reproducible by the measures. Comparison is carried out in different ways, the most common means of comparison is a comparator designed to compare measures of homogeneous quantities. An example of a comparator is a balance scale. Measures include standard samples and exemplary substance, which are specially designed bodies or samples of a substance of a certain and strictly regulated content, one of the properties of which is a quantity with a known value. For example, samples of hardness, roughness.

A measuring transducer (MT) is a technical tool with normative metrological characteristics that is used to convert a measured value into another value or a measuring signal that is convenient for processing, storage, indication or transmission. Measurement information at the output of the IP, as a rule, is not available for direct perception by the observer. Although IPs are structurally separate elements, they are most often included as constituent parts into more complex measuring instruments or installations and do not have independent significance during measurements.

The value to be converted, supplied to the measuring transducer, is called the input value, and the result of the conversion is called the output value. The ratio between them is given by the transformation function, which is its main metrological characteristic. For direct reproduction of the measured value, primary converters are used, which are directly affected by the measured value and in which the transformation of the measured value occurs for its further transformation or indication. An example of a primary transducer is a thermocouple in a thermoelectric thermometer circuit. One type of primary transducer is a sensor - a structurally separate primary transducer from which measuring signals are received (it "gives" information). The sensor can be placed at a considerable distance from the measuring instrument that receives its signals. For example, a weather probe sensor. In the field of ionizing radiation measurements, a detector is often referred to as a sensor.

By the nature of the conversion, IPs can be analog, analog-to-digital (ADC), digital-to-analog (DAC), that is, converting a digital signal to analog or vice versa. In the analog form of representation, the signal can take on a continuous set of values, that is, it is a continuous function of the measured value. In digital (discrete) form, it is represented as digital groups or numbers. Examples of IP are measuring current transformer, resistance thermometers.

A measuring device is a measuring instrument designed to obtain the values of a measured physical quantity in a specified range. The measuring device presents the measuring information in a form accessible to the direct perception of the observer.

According to the method of indication, indicating and recording devices are distinguished. Registration can be carried out in the form of a continuous record of the measured value or by printing instrument readings in digital form.

Direct action devices display the measured value on the indicating device, which has a graduation in units of this value. For example, ammeters, thermometers.

Comparison devices are designed to compare measured quantities with quantities whose values are known. Such devices are used for measurements with greater accuracy.

By action, measuring instruments are divided into integrating and summing, analog and digital, self-recording and printing.

Measuring installation and system - a set of functionally combined measures, measuring instruments and other devices designed to measure one or more quantities and located in one place (installation) or in different places of the measurement object (system). Measuring systems, as a rule, are automated and, in essence, they provide automation of the processes of measurement, processing and presentation of measurement results. An example of measuring systems are automated radiation monitoring systems (ASRK) at various nuclear physics facilities, such as, for example, nuclear reactors or charged particle accelerators.

According to the metrological purpose, measuring instruments are divided into working and standards.

Working SI - a measuring instrument intended for measurements, not related to the transfer of the unit size to other measuring instruments. The working measuring instrument can also be used as an indicator. An indicator is a technical tool or substance designed to establish the presence of any physical quantity or exceed its threshold value. The indicator does not have standardized metrological characteristics. Examples of indicators are an oscilloscope, litmus paper, etc.

Etalon - a measuring instrument designed to reproduce and (or) store a unit and transfer its size to other measuring instruments. Among them, it is possible to single out working standards of different categories, which were previously called exemplary measuring instruments.

The classification of measuring instruments is also carried out according to various other criteria. For example, by types of measured values, by type of scale (with a uniform or non-uniform scale), by connection with the object of measurement (contact or non-contact).

- In contact with 0

- Google+ 0

- OK 0

- Facebook 0